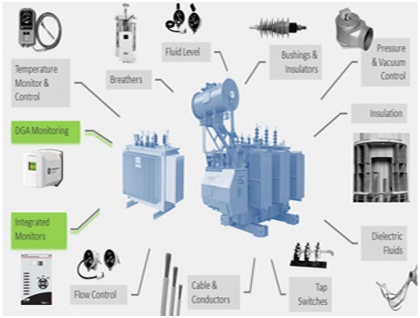

Identify equipment problems early before a failure can occur by monitoring the health of motors fans pumps and other rotating equipment.

Vibration monitoring system of industrial equipments using wireless communication.

Vibration sensors have been available for many years but older systems were costly to install limiting their deployment to the most expensive and critical rotating equipment.

Turn unplanned outages into manageable predictive.

Since it complies with lorawan which is a low power wide area lpwa network for long distance communication the xs770a can be deployed anywhere in a plant and cover a vast area.

The first product xs770a can measure vibration and surface temperature to monitor machine or equipment conditions for industrial use.

Limit machine failure rate through 24 7 vibration monitoring bently nevada s ranger pro wireless temperature and vibration sensing system reduces the frequency of sudden equipment failures by way of accurate and early detection of an issue.

Advantages of wireless condition monitoring systems.

Optionally this sensor may be externally powered making it an ideal choice for wireless vibration monitoring system for industrial equipment.

The project contributes directly to strengthening the european market in several key sectors such as quality control systems safety systems wireless communication and industrial automation and control systems.

The wibrate european fp7 project explores new paradigms for vibration monitoring and control using wireless intelligent sensors that power themselves using harvested vibration energy.

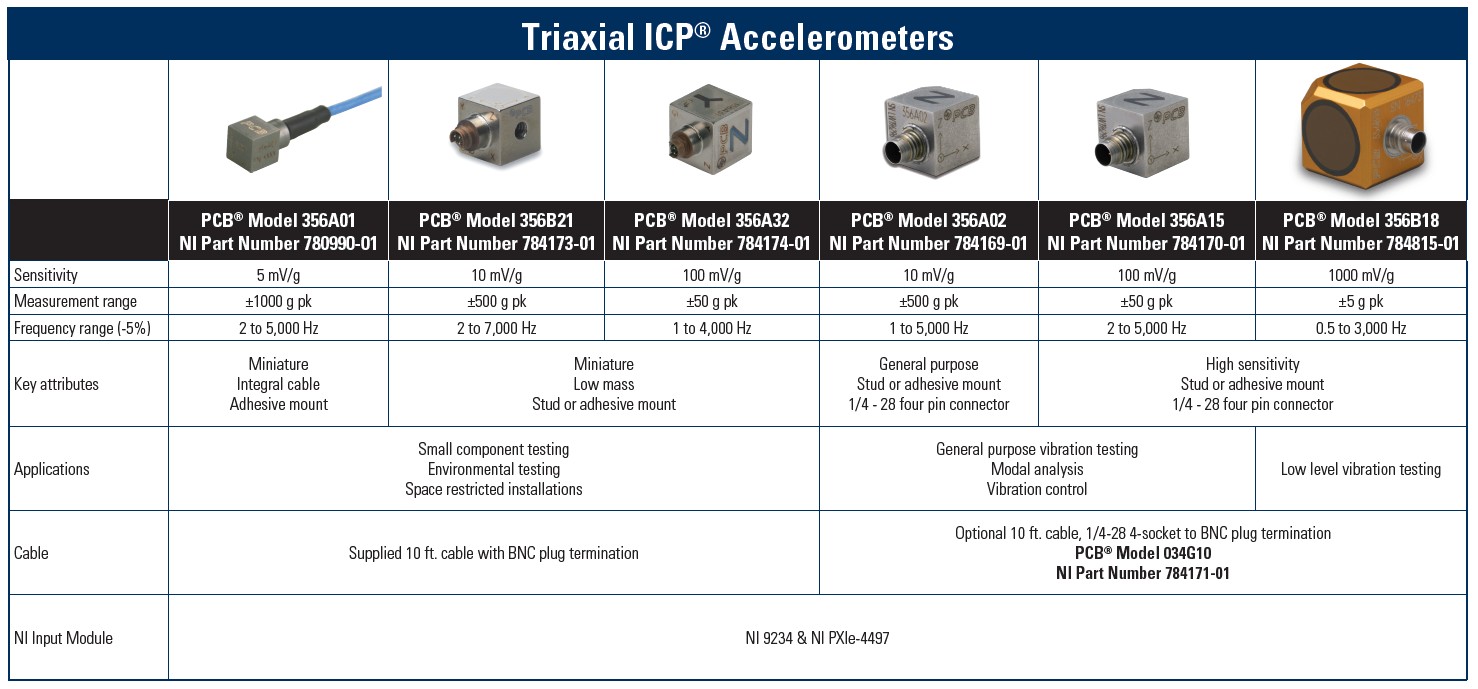

These vibration monitoring systems typically use a piezo electric sensor to create and transmit a signal proportional to measured vibration.

-1-LAV1.jpg?v=1)